Air turbines (traditional high speed handpieces) can be small, lightweight and rotate at high speeds, but torque can vary and noise levels are high.

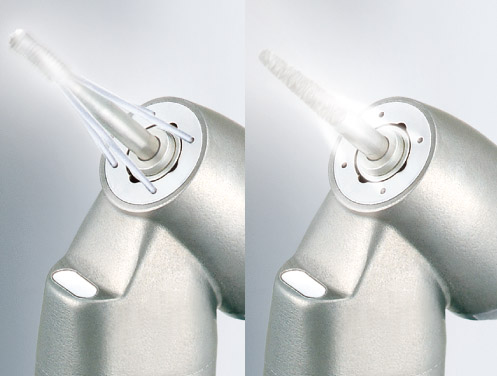

Electric driven, speed increasing contra-angles not only do everything a turbine does using the same FG burs, they provide a consistent torque from the micromotor that does not decrease with resistance and higher load with no loss of power as they come in contact with the tooth.

Electrically driven instruments are well-known for their flexible functionality and for operating at vastly reduced noise levels with reduced vibration for added patient comfort. Thanks to the torque control they provide a smooth and more precise cutting action that is generally considered to be superior to that provided by an air turbine.